When embarking an engineering project or just some good old-fashioned DIY, it’s easy to feel swamped by technical jargon and complicated equations – but this doesn’t have to be the case, at least when it comes down to the choice of wire to use, which, you may not know, extends beyond simply picking aluminium or copper.

The difference between solid and stranded wire is easy to understand, and which type of wire you will need for your project depends on the nature of the application. Both kinds of wire are suitable for residential and commercial applications, but each type has certain advantages and disadvantages that make them suited for particular uses. Read on to find out all you need to know.

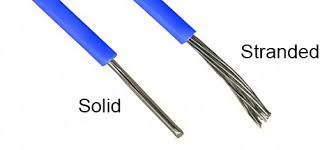

Solid-Core Wire

This kind of wire, as the name suggests, is comprised of one solid core of metal contained within an insulating material. This makes it cheap, simple and easy to manufacture. Solid wire also has excellent durability because it is merely a single strand of wire, making it very resistant to damage and decay. Solid wire, therefore, is the right choice for heavy-duty applications where the wire will be exposed to outdoor elements, adverse weather conditions and corrosive substances. As it is cheaper, it also makes sense to use it in installations where it will not move once put in place, such as in the walls of a house.

However, in installations where the wire will be subject to frequent movement, bending or vibration, such as in robotics, vehicles or consumer devices, solid wire is not very appropriate as it lacks the malleability and strength to withstand constant reshaping and movement. Solid wire may also not be the best choice when it is required that the wire be bent into complex shapes, such as in circuit boards. For these applications, stranded wire is the best bet.

Stranded Wire

Stranded wire is made up of many separate strands or threads of metal, held together by an insulating material. The presence of many different thin strands makes it perfect for intricate designs with many twists and turns, such as small consumer electronic devices and circuit boards.

Stranded wire can also much more easily tolerate vibration and reshaping. Headphone cables are a good example of this. In a domestic setting, if a wire has to be routed through small gaps or at sharp angles, stranded wire is best. Furthermore, the additional surface area created by having multiple strands of wire makes it ideal for efficient and effective heater core wire

It does have downsides, however. The gaps in between the strands allow moisture to collect, with nowhere to escape to, leading to corrosion, so solid wire may be more appropriate for outdoor installations. Additionally, the presence of these gaps in between the strands compared to a solid core also means that a stranded wire of a particular gauge will not be able to carry as much current as a solid wire of the same gauge.

Lastly, when seeking to prevent or minimise electronic interference, stranded wire is not an ideal option because the minute air channels between the strands amplify the skin effect generated by magnetic fields along the surface of the wire. Solid wire is the better choice in this situation.

Final Considerations

Solid wire costs significantly less initially, but stranded wire will deliver a far longer service life in environments where vibration, motion or frequent reshaping are likely to occur. Taking into account all of the above factors is vital before you make the decision about which type of wire is best suited for your particular application.