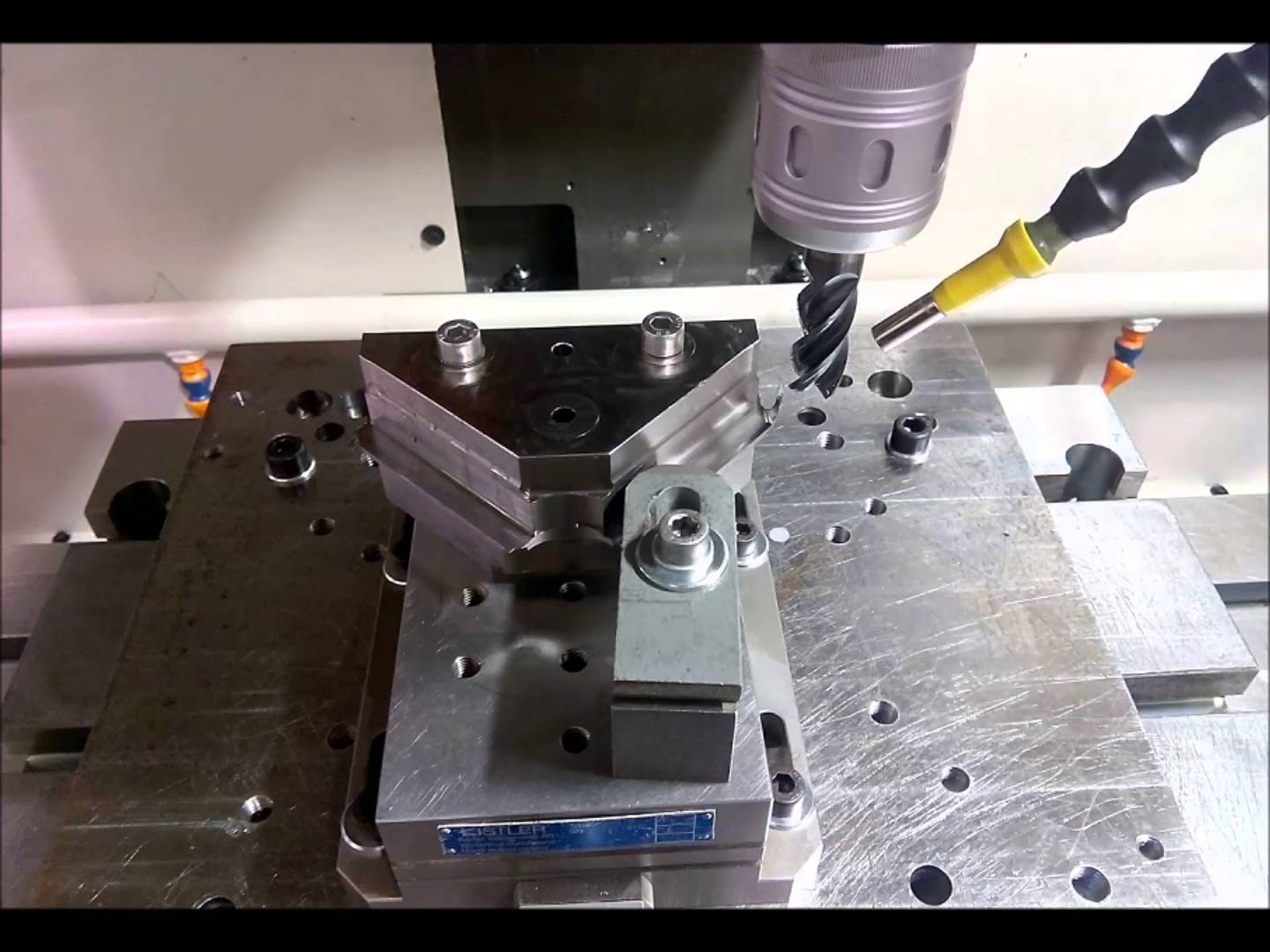

Keeping machining equipment cool enough to operate effectively is critical to staying in full production. Flooding coolant is the more traditional method, but the expense of storing coolants and resulting waste product is making the MQL method increasingly popular. Below are five benefits of switching to lubricant cooling of your equipment.

Environmentally Friendly and Safe

Protecting the environment has become important in all industries. trimming back on using harsh chemicals and finding alternatives that are earth-friendly is a goal most strive to reach. Customers of your products will feel better about doing business with a company that cares about environmental concerns. Reducing your employees exposure to toxic chemicals is also another benefit that guards the health and wellness of your staff.

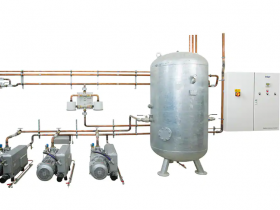

Cost-Effective for Any Size Operation

Any machining operation can benefit from the cost-savings of switching to an MQL cooling system. Systems can be put in place that will work for two or three machines, or whole industrial complexes can be outfitted with this method of reducing heat on parts. The larger the operation is, the more savings you will realize from the elimination of large quantities of coolant and removal of used product.

Eliminates Waste Product

Traditional flooding coolant processes all have the same concern over how to deal with used coolants. It is out of the question to dump them in dumpsters and other standard trash bins. The chemicals will make their way to unprotected areas of landfills and end up in the local water table. Special services have to be hired for removal and disposal.

Provides More Consistent Machine Use

How much more would get done each day if the equipment did not have to get shut down for parts cleaning, or to change the used coolant? A few hours a week saved translates into real money over the course of a week, month, or year. Lubrication cooling allows for the operation to continue as long as it is needed.

Customize the Cooling System

Most parts associated with a MQL cooling system are adjustable and be custom fitted for your particular operation. Lengths of hose, nozzle options, application specialties and much more can be added to ensure all of your machining equipment is getting maximum lubrication benefits.

Contact machine equipment lubrication experts like MagLube and schedule an appointment to set up a minimum quantity lubrication system right away!