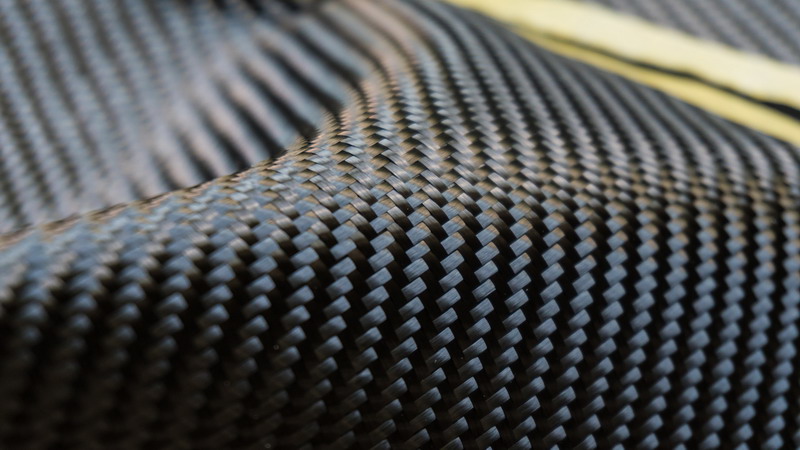

Turning carbon fiber prepregs into finished parts requires a manual lay-up process that can be rather labor-intensive. But for many fabricators, seeing the finished product makes all the work very much worth it. They understand that there are trade-offs when working with carbon fiber materials, just as there are in any other industry.

One place those trade-offs can be seen is the Ferrari Land Theme Park in Spain. The park offers two attractions built with a focus on carbon fiber panels. Though neither attraction is made exclusively from composites, the composite parts that can be seen are truly breathtaking.

A Beautiful Composite Facade

Both the Ferrari Experience and Red Force buildings were constructed using a combination of aluminum and carbon fiber panels. The carbon fiber really shines, so to speak, on the buildings’ exteriors. Take the Ferrari Experience building as an example.

The front of this building looks remarkably like the front end of a Ferrari sports car. A molded hood acts as a canopy while the grill completes the building’s main entrance in concert with heavy glass doors. The facade could not have been constructed as well as it was without the use of composites.

Herein is the first trade-off of carbon fiber layups. The manual layout process allows for creating all sorts of unique shapes in lines that are governed only by a fabricator’s ability to make the right kind of mold. Creating the same facade using aluminum or steel panels would have been next-to-impossible. Doing it with concrete would have been time-consuming and costly.

The trade-off is in waste. As explained by the experts Rock West Composites, creating fiber panels using a manual layup always result in wasted carbon fiber material. And until someone figures out a cost-effective way to recycle that waste, its only destination can be a landfill.

Trade-Offs in Cost

To be clear, fabricating with carbon fiber is not the perfect solution for every need. For example, one of the reasons that carbon fiber has not been more widely adopted in the automotive industry is cost. It is a lot less expensive to manufacture parts out of aluminum alloys than it is carbon fiber. And in terms of automotive body panels, aluminum and fiberglass are a lot less expensive.

Auto makers can create beautiful carbon fiber parts that are stronger and more durable than aluminum and steel. Those same parts can withstand more punishment as well. But the trade-off is cost. A new car heavy on the carbon fiber would cost a lot more than a traditionally-made vehicle.

On the other hand, manual carbon fiber layups make it easier for manufacturers to bring concept cars to life. Keep in mind that designers have to pay attention to the material being used to car build when coming up with their concepts. Carbon fiber makes possible what is generally considered impossible for aluminum and steel.

Learning to Make It Work

There is no building or fabricating material that is 100% perfect in every way. So designers and fabricators have to work with what they have. The nice thing about carbon fiber and other composite materials is that we are learning better ways to make them work.

Fifty years ago, it would have been inconceivable to make a building facade out of carbon fiber panels. Today it is not only conceivable, but it is also economically viable. Thanks to manual layups, prepregs, and very talented designers who are also artists in their own right, we are being treated to some beautiful architecture unlike anything the world has seen before.