An abrupt disruption to your television reception, bizarre noise spoiling your favorite radio program, sudden craziness displayed by your computer monitor – are incidences like these driving you insane? Don’t call an exorcist yet, for it might just be electromagnetic interference (EMI), a kind of radiated energy that affects electrical circuits of complex machines, preventing them from functioning properly. These invisible energy waves not only damage electronics, they have lethal effects on human health. And this is not all; if left unchecked EMI may create massive radio frequency ‘spectrum pollution’ and can negatively impact the society with massive economic consequences. Different types of shielding solutions are used to reduce the electromagnetic field in a space. Made of conductive magnetic shielding materials, these specially designed barriers help block the emission or minimize the intensity of magnetic field.

Shielding Basics:

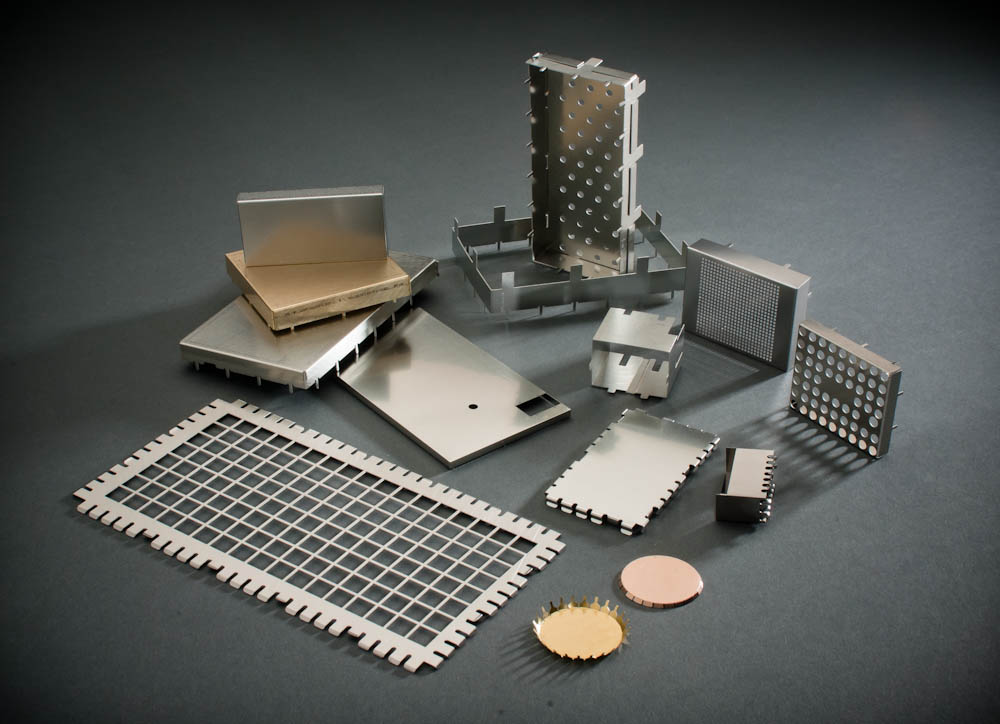

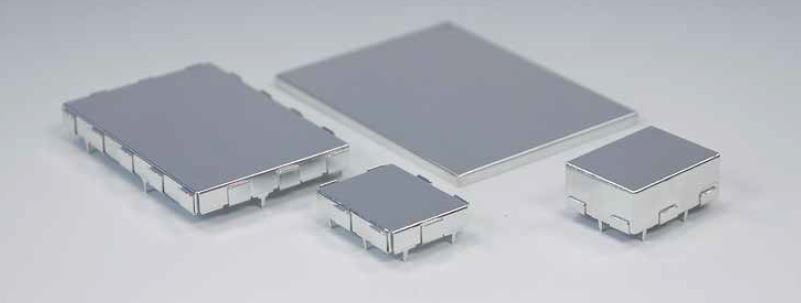

EMI shields are designed to protect electronic circuits from electro-magnetic field interference. These protective barriers serve two basic purposes:

First, they prevent strong field radiation from sources such as transformers, magnets, motors, cables and solenoids. They even minimize cross-talk between circuits, so that the device can function properly.

Secondly, they create a shielding layer around electronic devices and protect them from magnetic fields in an environment.

These specially engineered metallic enclosures create a path around sensitive areas in a device and help magnetic flux – the rate of flow of magnetic field – deflect through this path.

In addition, EMI shields may absorb magnetic flux around a component that generates it.

Types of Magnetic Shielding Materials:

In Physics, the ability to conduct magnetic flux is referred to as permeability. Depending on their level of permeability, magnetic shielding materials can be divided into three categories – high permeability, medium permeability, and high saturation.

In the domain of magnetic shield, the degree of permeability is expressed numerically.

High permeability materials have a minimum permeability value of 80,000 at B-40 and a maximum of 350,000 with a saturation point of about 7,500 gauss after heat treating.

Medium permeability materials have minimum and maximum permeability values of 12,500 and 150,000 respectively with a saturation point of about 15,500 gauss.

For high saturation materials, saturation points vary between 18,000 and 21,000 gauss. They have a low permeability count with the minimum and maximum value ranging from 200 to 50,000.

The Ideal Materials for Magnetic Shielding:

Any ferromagnetic metal – one that is composed of iron, nickel or cobalt – makes a good shielding solution. Steel is the least expensive of all ferromagnetic metals, yet it works very efficiently when it comes to redirecting emission. It is widely available all over the world. No wonder, steel is by far the most popular choice as far as shielding materials are concerned. It is ideal for applications that call for a small attenuation (the rate of reduction in magnitude of electromagnetic field strength) of a high flux density field. Not all types of steel have ferromagnetic qualities, though. Some stainless steel varieties such as the 300 series steel are not fit for magnetic shielding.

Shielding Materials Other Than Metal:

Apart from metals, shielding solutions can be made of many other composite materials. They typically have a higher relative permeability, but a lower saturation point. MuMetal is by far the most commonly used material. It is widely used by shielding solution providers to create their proprietary alloys. Most of these composite materials are characterized by their high nickel content, which generally vary between 50 to 80 percent.

To be effective, EMI shields should be composed of the right materials. Choose magnetic shielding materials according to your specific shielding needs. While MuMetal will offer the best answer in many cases, sometimes, especially when dealing with large, powerful magnetic fields, you need to count upon the high saturation point of steel. Talk to your shielding solution provider for the options that work best for you.