Isolating sensitive and expensive electrical devices and appliances from magnetic fields can assure their performance. The magnetic shielding materials come with permeability attribute and their structure absorbs magnetic interference to keep the shielded device and appliance safe. Let us discuss about how this shielding process works and what kind of materials we need for protection against magnetic fields.

Magnetic Shielding Work Process

Magnetic shielding is all about absorbing and re-directing the magnetic lines of flux. Yes, we said absorbing not blocking. It is a common myth that shielding options can help you block the magnetic fields. But, research has proven otherwise. Nothing can block or destroy magnetic fields. Shields offer the field a redirection away from its target. In some cases, magnetic fields can interfere with sensitive electrical devices and tamper with their performance level. Creating an enclosed space with shielding materials to surround the equipment can offer benefit.

To work efficiently, the shielding materials have to have high magnetic permeability. Metal alloys or coatings with ‘nano-crystalline’ structure are generally used as the shielding material. MuMetal has shown promising results in absorbing and re-directing the magnetic lines better than other materials. But can MUMetal live up to its reputation in delivering the best shielding from magnetic fields? Let’s see.

Composition of MuMetal

MuMetal has 80 percent nickel, 4.5 percent molybdenum, and iron, which adds to its permeable attributes. This specific composition absorbs and re-directs the magnetic field lines effectively. Therefore, enveloping an area with a hollow structure of MuMetal sheets can keep the magnetic field interference at bay.

Application of MuMetal as Shielding Material

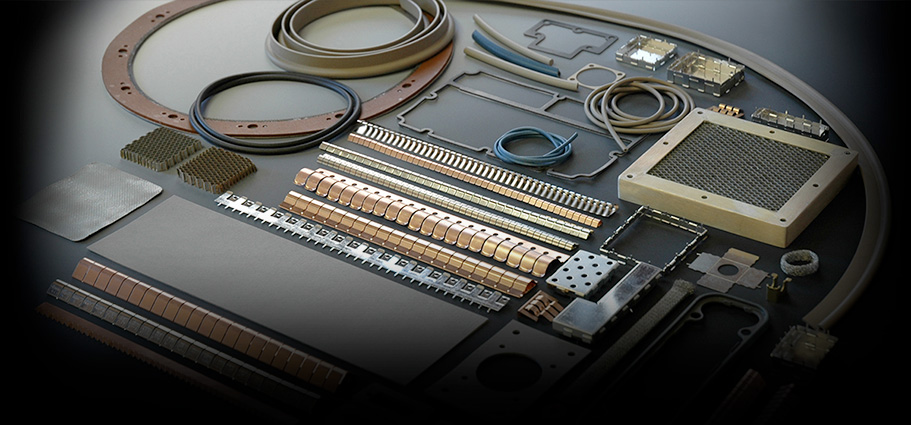

You can use MuMetal to cover an array of requirements that involve small daily usage necessities to enterprise class solution development. You can shield speakers from magnetic fields or can go for shielding a whole room with MuMetal for protection against magnetic fields. When using shielding materials, try to go for a round or cylindrical shape, as fewer joints and less sharp angles produce better results in re-directing the magnetic field lines.

A Closer Look at MuMetal

If viewed on a microscopic scale, MuMetal can be considered to be a crystalline structure with magnetic domain. In the last stage of manufacturing the shield, MuMetal is treated with a special heat treatment. This ensures the highest shielding performance.

MuMetal Works Well With Buffer Layers

In medical and industrial fields, re-directing medical lines precisely and effectively is extremely important. In such work areas, strong shielding operations are implemented to re-direct magnetic fields. Therefore, using a buffer layer over the primary shielding material seems wise to let the primary shielding material work within its saturation capability. MuMetal can work well with buffer layers and effectively cut down the saturation level with ease.

MuMetal Can Work With Both AC and DC

AC or alternating current changes its direction in a period of time. Magnetic fields from AC currents are generated by sources that use 50-60 Hz electrical power. However, DC or direct current always travels to one direction without fail. Although, AC and DC have different features and characteristics, Mumetal can work well with them as magnetic shielding material.

For better performance and longevity of electrical appliances, isolating and protecting them from magnetic shield is a wise idea. In fact, effective shielding is critical in many cases. Although MeMetal is very effective, it does veer towards the expensive side. The reason is its apparent scarcity. In other words, this shielding material is manufactured by only a few specialty steel mills and in small batches. However, if cost is an issue while choosing the right types of magnetic shielding materials, you must talk to the relevant service providers for cost-effective solution. Keep this information handy for understanding the process better.